We support custom oak slim shaker kitchen cabinets for projects. For many years, we have adhered to the philosophy that quality and on-time delivery are always our top priorities.

Item No :

Oak Wood CabinetsOrder(MOQ) :

One containerPayment :

TTProduct Origin :

VietnamColor :

OakShipping Port :

Ho Chi MinhLead Time :

45-60 daysCustom oak slim shaker kitchen cabinets use oak as the core material, continuing the minimalist essence of the Shaker style while innovatively adopting a slim-frame design to fit modern homes, making them a popular choice for projects that balance aesthetics and practicality.

At Union Woods, we use genuine U.S.-imported oak for our cabinet panels, resulting in exceptional performance. Regardless of the material used as the cabinet substrate, it undergoes strict screening, and only wood that meets quality standards is used.

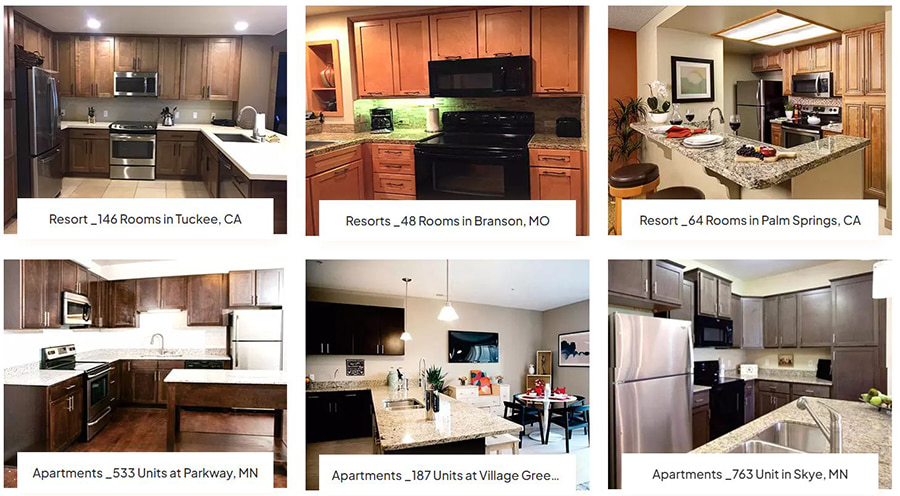

As a kitchen cabinet supplier, our factory in Vietnam has sample cabinets so you can experience the quality more intuitively. Various colors and styles are displayed together for comparison, helping you find your dream cabinets more quickly.

Table of Contents

Specification For Wholesales

| FRAME | SOLID WOOD (1-1/2"W; 3/4"T) |

| BOX/CARCASS MATERIAL | 1/2" PLYWOOD |

| DOOR | SOLID WOOD WITH MDF CENTER PANEL |

| DRAWER BOX | 5/8" SOLID WOOD WITH DOVETAIL CONSTRUCTION |

| HINGE | SOFT CLOSING ADJUSTABLE CONCEALED HINGES |

| SHELVES | 3/4" PLYWOOD |

| TOE KICK | 1/8"PLYWOOD |

| GLIDES | FULL EXTENSION UNDERMOUNT SOFT CLOSE |

Slim Shaker Kitchen Cabinets Design Concept

1. The Slim Shaker collection breaks through the wide-frame design of traditional Shaker cabinets, replacing it with a slim-line profile that aligns with modern aesthetics.

2. Featuring cleaner, more fluid lines, Slim Shaker cabinets eliminate excess ornamentation to create a visually lighter and more transparent kitchen space, embodying the "less is more" design philosophy.

3. Maintaining the classic construction, Slim Shaker door panels are crafted from four stiles and rails surrounding a center panel. The subtle indentation of the center panel adds a distinct sense of visual depth and dimension.

Customizable Surface Finishing Processes

The surface finishing of cabinetry is a critical factor that determines both the aesthetic appearance and durability. Our Vietnam factory offers customization for a wide range of common techniques. Each finish has unique characteristics, allowing for selection based on project budget and application environment.

1. Painting

The painting process involves multiple spray coats to create a smooth, full-bodied finish. Various gloss levels are available, offering different light reflectivity to suit diverse projects. For oak cabinetry, clear lacquer is most commonly selected to highlight the natural wood grain and preserve the tactile texture.

2. UV Coating

After spraying UV paint, oak undergoes ultraviolet curing. This results in a flat, plump, and smooth paint film. The curing process is fast and environmentally friendly, though the equipment cost is relatively high. However, our Vietnam factory utilizes state-of-the-art machinery to achieve a superior paint finish.

3. Thermofoil

Thermofoil is a surface decoration method using heat transfer technology. Selected patterns are permanently bonded to the cabinet wood surface through high temperature and pressure. Compared to painting, this process eliminates multiple steps, thereby improving production efficiency. Furthermore, the material has zero formaldehyde emissions, making it highly environmentally friendly.

4. Melamine

Melamine resin is used as the facing material. Paper with different colors or textures is impregnated in melamine resin adhesive, then dried to a specific curing degree and pressed with heat. This finish offers advantages such as wear resistance and heat resistance. It is also cost-effective and provides a vast selection of textures and patterns.

Meeting Project Personalization Needs

The advantage of custom oak slim shaker kitchen cabinets for projects is that they are fully customizable across all dimensions. Size, structure, and functionality can all be tailored to project requirements, satisfying the differentiated needs of various projects.

1. Size and Layout Customization

Cabinets can be customized according to the actual dimensions of the kitchen, ensuring no space is wasted. Based on the kitchen layout, we offer configurations such as straight, L-shaped, U-shaped, and island combinations to fit different unit types. The height, width, and depth of the cabinets are all adjustable. Even for irregularly shaped spaces, we can produce custom-fit cabinets to ensure a perfect installation fit.

2. Functional Structure Customization

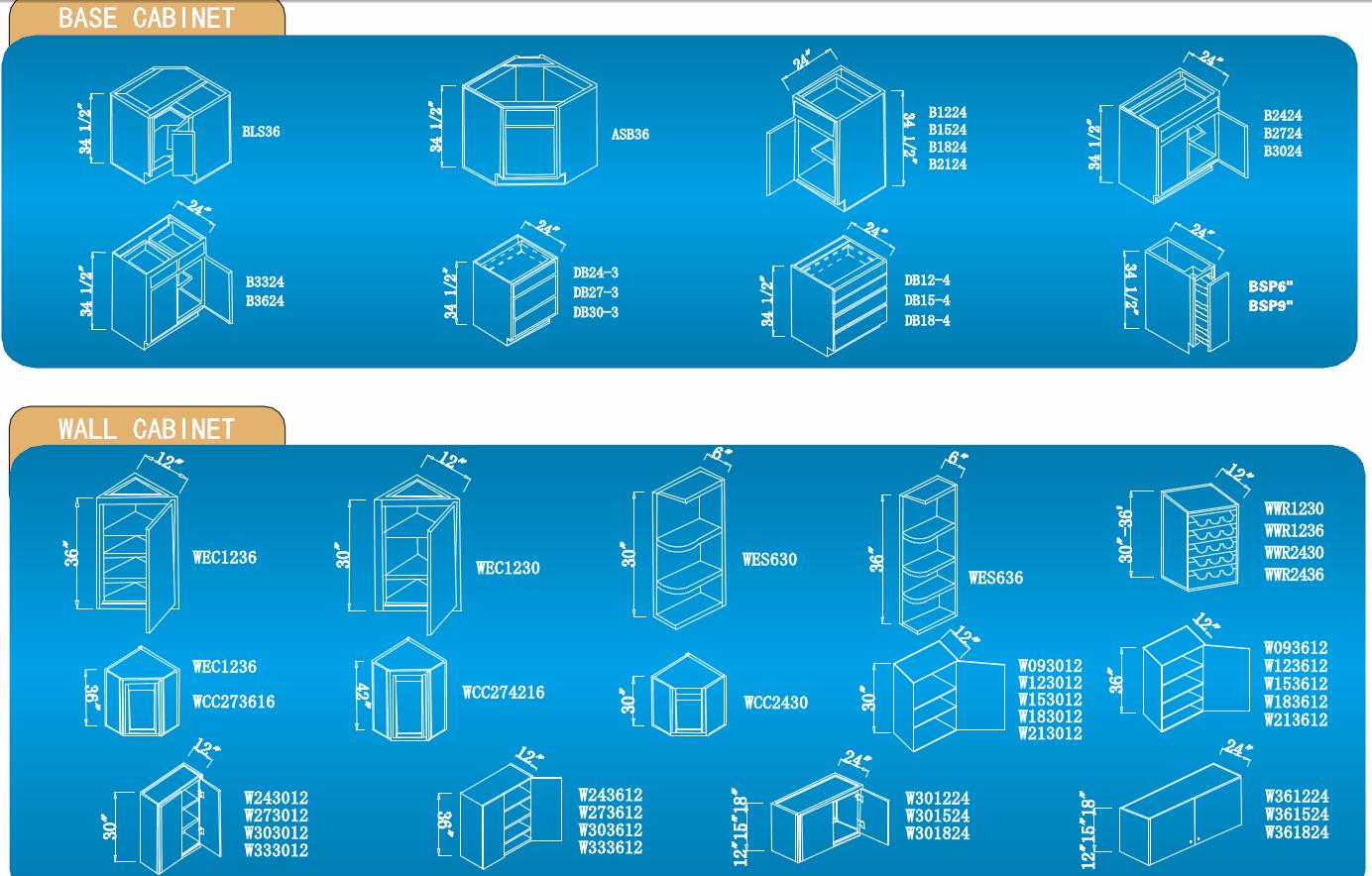

Storage functionality can be optimized as needed. Standard configurations include base cabinets, wall cabinets, tall cabinets, and drawer cabinets. We also support customization for pull-out baskets, corner carousels, and built-in appliance garages to enhance kitchen convenience. For commercial projects, we can further customize features like spice racks and removable shelf lighting to improve practicality.

3. Hardware and Accessory Customization

We use concealed soft-close hinges and damped drawer slides. Handle customization is supported, with options including invisible handles, bar handles, and vintage knobs to elevate the detailed texture of the design.

Applications of Oak Slim Shaker Kitchen Cabinets

With their material advantages, design flexibility, and functional practicality, this series of custom oak slim shaker kitchen cabinets is suitable for a variety of project scenarios:

Home Renovation Projects:

Suitable for kitchens in apartments, villas, condominiums, and other residential properties. They can be customized according to the homeowner’s aesthetic preferences and lifestyle habits, creating a kitchen space that is both personalized and practical.

Commercial Space Projects:

Ideal for kitchens in high-end serviced apartments, boutique homestays, upscale restaurants, and other commercial venues. Through style customization and overall spatial design, they can perfectly complement the ambiance of the commercial setting.

Production and Service Assurance

To ensure the smooth progress of your project, as a kitchen cabinet wholesaler, we provide comprehensive production and service support:

Production Lead Time:

The lead time for custom orders is 45-60 days from placement to delivery. We can also adjust the production schedule to align with your specific project timeline.

Quality Assurance:

All products undergo strict pre-shipment inspections to ensure the materials, craftsmanship, and dimensions meet your custom requirements. We also provide a warranty service for added peace of mind.

Service Support:

We offer end-to-end services including design consultation, custom solution planning, and installation guidance. Our professional team is dedicated to assisting with any issues that may arise during the project to ensure its successful execution.

Union Woods’ Customization Advantages

Unlike other kitchen cabinet wholesalers, we support both wholesale and custom services, with specific strengths in custom kitchen solutions.

1. Wide Selection of Materials and Colors

Headquartered in Vietnam, we operate one of the large, modern cabinet factories with comprehensive equipment. This allows us to offer a diverse range of materials and colors to meet your customization needs, suitable for both framed and frameless cabinetry.

2. Quality Assurance

Cabinet quality is our top priority. From raw material selection to production details and final packaging, every step is carefully managed to ensure premium quality and a perfect delivery to your destination.

3. On-Time Delivery

When you choose our custom service, we guarantee on-time delivery. We understand the importance of timely arrival for your project, so we account for all factors and act according to the planned schedule.

4. Competitive Pricing

With direct supply from our Vietnam factory, you can enjoy factory wholesale prices when customizing with us. For the same quality, our quotes are particularly favorable.

5. Vietnam and U.S. Service

Union Woods not only has a professional team but also warehouses on both the East and West Coasts of the United States. This enables us to respond quickly to after-sales service and complete replenishments at a faster speed.

Frequently Asked Questions (FAQ)

Q1: Do custom oak slim shaker kitchen cabinets for projects comply with North American building codes and kitchen size standards?

A: Yes, they fully comply. We have a professional design team well‑versed in North American kitchen size specifications and building codes. All cabinets are custom‑made to your project’s specific dimensions, and we provide relevant certification documents to ensure compliance with local regulations.

Q2: Is there a discount for bulk custom oak slim shaker cabinets for projects?

A: Yes. We offer tiered discounts based on the order quantity—the more sets you customize, the larger the discount.

Q3: How should custom oak slim shaker cabinets be maintained for long‑term use?

A: Clean daily stains with a soft, damp cloth. Keep the kitchen well‑ventilated and avoid prolonged exposure to direct sunlight.

Q4: Can I get samples of custom oak slim shaker cabinets before placing a project order?

A: Yes. We provide oak samples for free. If you need samples of other materials, please contact us, and we can send them together for your reference.

Q5: Can the cabinet design be modified during the production of custom oak slim shaker kitchen cabinets for projects?

A: Modifications are allowed only if production has not entered the wood cutting and shaping stage. If you need to adjust dimensions, colors, or hardware types before this stage, we can make the changes free of charge.